Contamination from uranium ore mining:

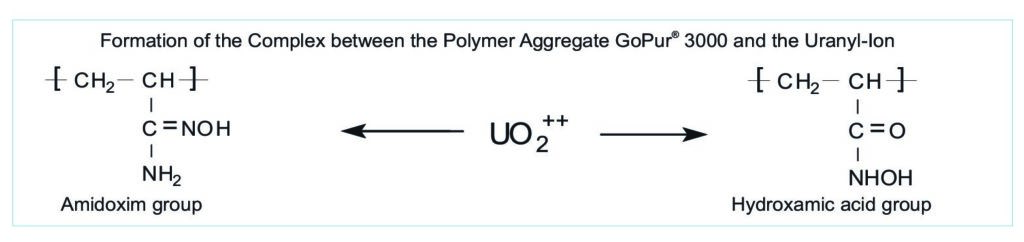

The polymer aggregate GoPur®3000:

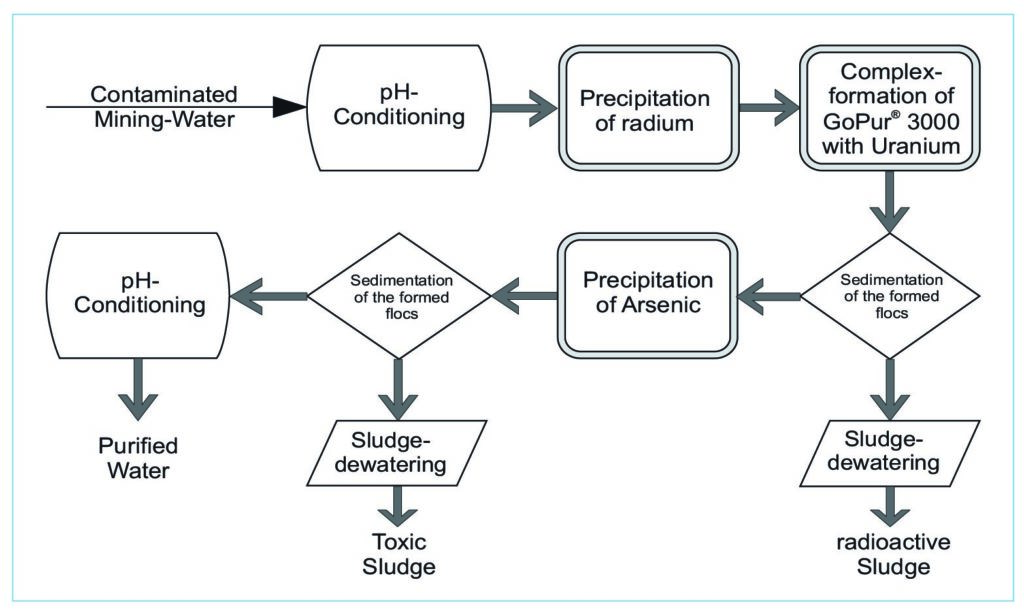

A characteristic of the new process is the combination of known methods for precipitating the radium and arsenic compounds with uranium separation using the GoPur® 3000 polymer aggregate. The process sequence is divided into the joint separation of the radioactive water components radium and uranium and the separate precipitation of the toxic arsenate . First, a barium sulfate precipitation is triggered in the weakly acidic water by dosing a soluble barium compound, in which the radium compounds are bound by co-precipitation. Then, without isolating the sulphate precipitate, it is flocked with the GoPur® 3000 polymer aggregate.

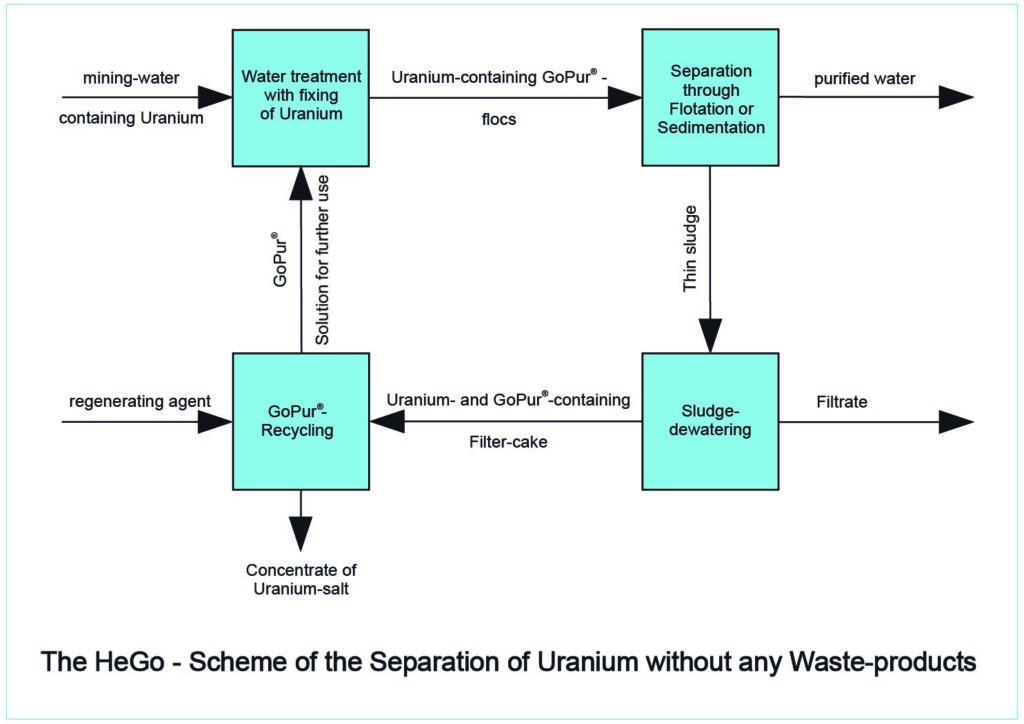

The specific chemical structure of the polymer aggregate guarantees not only a highly effective complex binding of the uranium, but also intensive floc formation through molecular aggregation. The radioactive flakes are separated by sedimentation. In a second stage, the arsenic can be precipitated as iron arsenate in the water which has then been pre-cleaned and also separated by sedimentation. The polymer aggregate can be recovered by simple dissolving and washing processes of the radioactive sludge.